Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

Application: Baby diaper, Adult diaper, Sanitary napkin

Minimum order quanity: 1000.00 kgs

Packing details: Transparent wrapping film with paper board

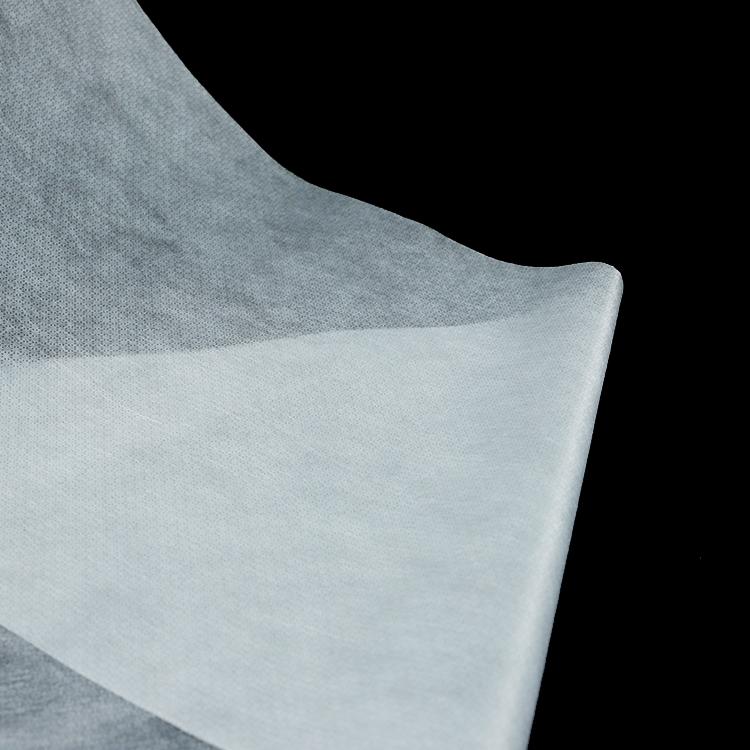

OEM&ODM Baby Diapers Raw Material-Non Woven Fabric

1. Main application areas

(1) Baby diapers/pull-up pants

Top Sheet: Direct contact with baby skin, the softness and breathability of the hot air non-woven fabric reduce the risk of rash, and the high fluffiness enhances comfort.

Diversion layer: Some designs use hot air non-woven fabric to promote rapid liquid penetration and avoid reverse osmosis.

Waist circumference/side wings: Elastic hot air non-woven fabric provides a soft fit and prevents creases.

(2) Female hygiene products (sanitary napkins, pads)

Surface material: Hot air has no cilia and is skin friendly, suitable for sensitive skin. Some products enhance dryness and feel through embossing technology.

Back layer breathable film composite: used in combination with breathable film to balance leak prevention and breathability.

(3) Adult incontinence products

Absorbent core wrapping layer: The high-strength hot air non-woven fabric (such as SMS structure) prevents fiber shedding while maintaining breathability.

Stereoscopic enclosure: combined with elastic materials to prevent side leakage.

(4) Medical protective pads/bed pads

Disposable mattress surface: The antibacterial modified version of the hot air non-woven fabric can be used in medical scenarios, balancing comfort and hygiene.

2. Performance advantages

Softness and comfort: Fiber fine denier technology makes the touch feel similar to textiles.

High strength: The spunbond process provides excellent longitudinal/transverse tensile strength, suitable for high-speed production.

Chemical stability: No reaction to bodily fluids such as sweat and urine, safe and non irritating.

Processability: Easy to composite with other materials such as meltblown fabric and PE film, meeting multifunctional requirements.

|

Items |

Unit |

Requirement |

Result |

|

|

Color |

|

White |

white |

|

|

Core inside diameter |

mm |

76±1 |

76 |

|

|

Roll slit width |

mm |

160±2 |

160 |

|

|

Basic weight |

g/m2 |

18±1.5 |

17.91 |

|

|

Through time |

S |

1st: ≤2 |

1.35 |

|

|

2nd: ≤3 |

2.29 |

|||

|

3rd: ≤4 |

2.47 |

|||

|

Breaking tension |

MD |

N/5cm |

≥28 |

32.98 |

|

CD |

≥15 |

17.82 |

||

|

Breaking elongation |

MD |

% |

/ |

54.86 |

|

CD |

/ |

61.79 |

||

|

Others |

Wrinkles/ corrugation |

None |

||

|

Splices |

None |

|||

|

Roll edge appearance |

Neat, Clean, No Obvious Defects |

|||

|

Contamination |

No Obvious Contamination; Free From Foreign Matter |

|||

|

Holes/Thin spots/Formation |

No Obvious Holes / Thin Spots / With Good Formation |

|||

Our Certificate

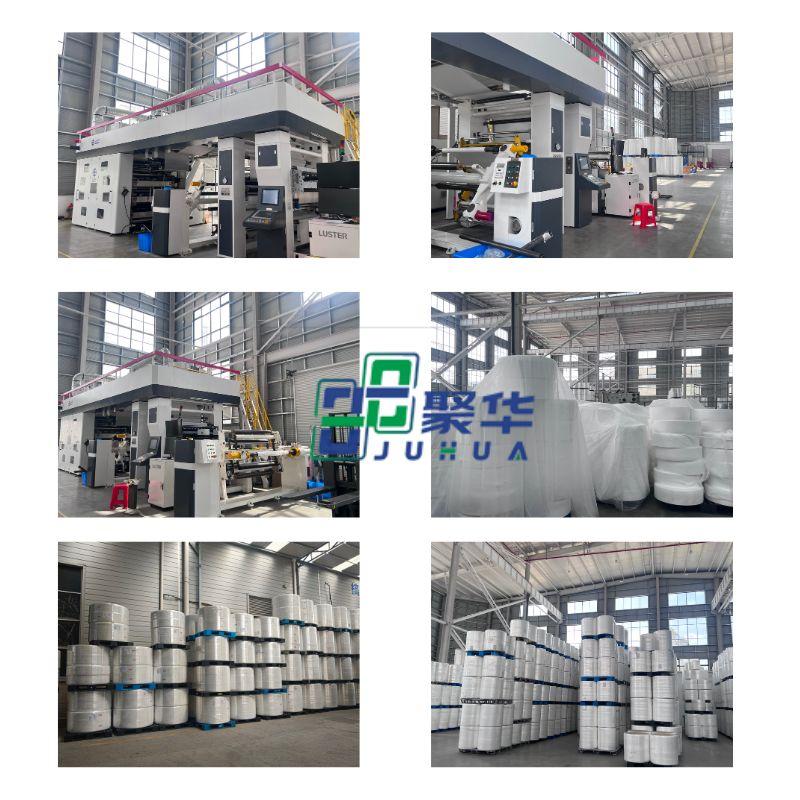

Juhua Factory

Backsheet non woven fabric for economic diaper and pull-ups. WIDTH BASIC WEIGHT Width 70-3200mm Basic weight 10-200g/m² CHARACTERISTIC Normal soft...

Durable, disposable. Insulating,conducting. Softness, stiffness. fineness, expansion. Isotropic, anisotropic.Filterability, breathable and impermeable. Elasticity, stiffness. Ligh...

Weight: 18 – 50gsm Width: 65mm-3600mm Inner core diameter: 76mm Outer diameter:580-780mm Loading quantity:9-10tons/40HQ Items Unit Requirement Resul...

SSSspunbond polypropylene hydrophobic non woven fabric features: 1. Polypropyleneis the key component of the sterile quality of spunbond non woven fabrics. 2.Thematerial ...

Weight: 18 – 50gsm Width: 65mm-3600mm Inner core diameter: 76mm Outer diameter:580-780mm Loading quantity:9-10tons/40HQ Items Unit Requirement Resul...

As a professional raw material supplier for disposable hygiene products , we are committed to delivering high-quality and customized solutions to global clients. Recently, we partnered with a well-k...

Boosting Brand Traffic Growth for South American Customers - Successful Practice of Foreign Trade Disposable Hygiene Products Factory Customer background Our client is a South American brand specializ...

1. Customer Background The client is a hygiene products manufacturer based in the United Kingdom, mainly producing baby diapers and adult care products with a sales network covering multiple Europea...

Learn more about diaper materials!