Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

Application: Sanitary napkin,Baby diaper,Adult diaper

Minimum order quanity: 1000.00 kgs

Packing details: Paper board with transparent film

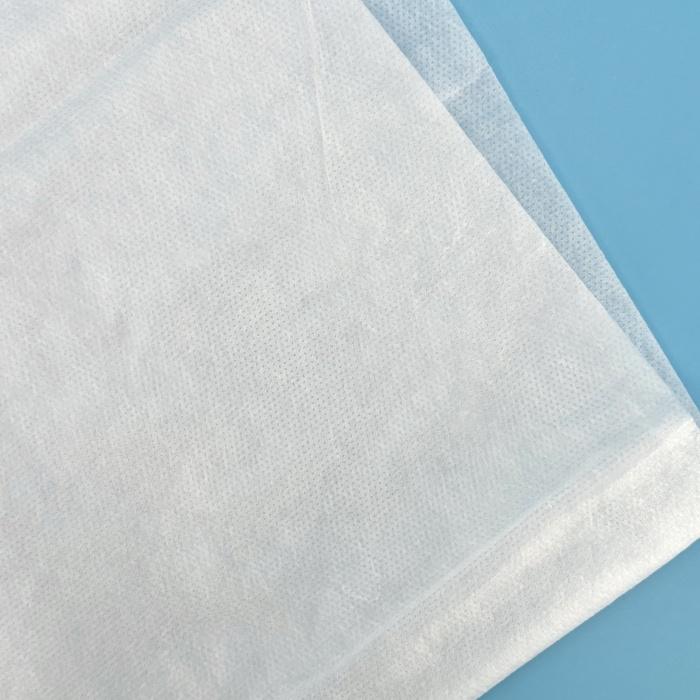

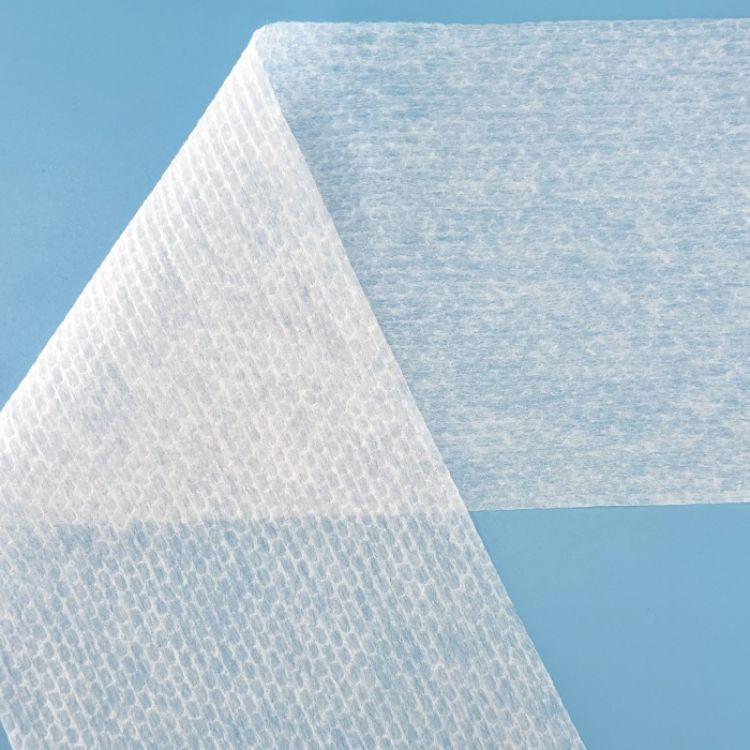

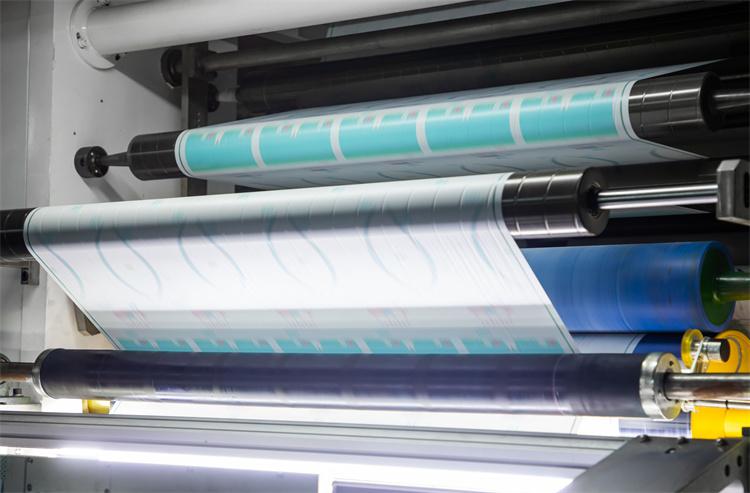

Hot Air Through Technology in Double-Layer Nonwoven Materials for Baby Diapers

1. Main application areas

(1) Baby diapers/pull-up pants

Top Sheet: Direct contact with baby skin, the softness and breathability of the hot air non-woven fabric reduce the risk of rash, and the high fluffiness enhances comfort.

Diversion layer: Some designs use hot air non-woven fabric to promote rapid liquid penetration and avoid reverse osmosis.

Waist circumference/side wings: Elastic hot air non-woven fabric provides a soft fit and prevents creases.

(2) Female hygiene products (sanitary napkins, pads)

Surface material: Hot air has no cilia and is skin friendly, suitable for sensitive skin. Some products enhance dryness and feel through embossing technology.

Back layer breathable film composite: used in combination with breathable film to balance leak prevention and breathability.

(3) Adult incontinence products

Absorbent core wrapping layer: The high-strength hot air non-woven fabric (such as SMS structure) prevents fiber shedding while maintaining breathability.

Stereoscopic enclosure: combined with elastic materials to prevent side leakage.

(4) Medical protective pads/bed pads

Disposable mattress surface: The antibacterial modified version of the hot air non-woven fabric can be used in medical scenarios, balancing comfort and hygiene.

2. Core advantages

Soft and fluffy: Fibers are bonded by hot air instead of chemical adhesives, making them more suitable for sensitive areas.

Good breathability: The porosity between fibers is higher than that of spunbond non-woven fabric, reducing the feeling of stuffiness.

Cost controllable: The production process is simple and suitable for large-scale production.

Customizability: By adjusting the fibers (such as ES fibers, polyester/viscose blends), the performance (water absorption, strength, etc.) can be changed.

|

Items |

Unit |

Requirement |

Result |

||

|

Min |

Max |

||||

|

Color |

/ |

white |

white |

||

|

Core inside diameter |

mm |

76±1 |

76 |

||

|

Basic weight |

gsm |

18±2 |

17.2 |

18.9 |

|

|

Width |

mm |

180±2 |

179 |

181 |

|

|

3D- Dimensional Thickness |

mm |

-0.2+0.3 |

0.43 |

0.49 |

|

|

Tensile strength |

MD |

N/5cm |

≥11 |

12.9 |

15.5 |

|

CD |

≥1.7 |

2.4 |

3.5 |

||

|

Breaking elongation |

MD |

% |

≥18 |

54 |

60 |

|

CD |

≥20 |

95 |

115 |

||

|

Fluid Penetrating Rate |

1st |

S |

≤2 |

1.03 |

1.25 |

|

2nd |

≤3 |

2.04 |

2.37 |

||

|

3rd |

≤4 |

2.6 |

3.01 |

||

|

Others |

Wrinkles/ corrugation |

None |

|||

|

Roll edge appearance |

Neat, Clean, No Obvious Defects |

||||

|

Contamination |

No Obvious Contamination; Free From Foreign Matter |

||||

|

Holes/Thin spots/Formation |

No Obvious Holes / Thin Spots / With Good Formation |

||||

Our Certificate

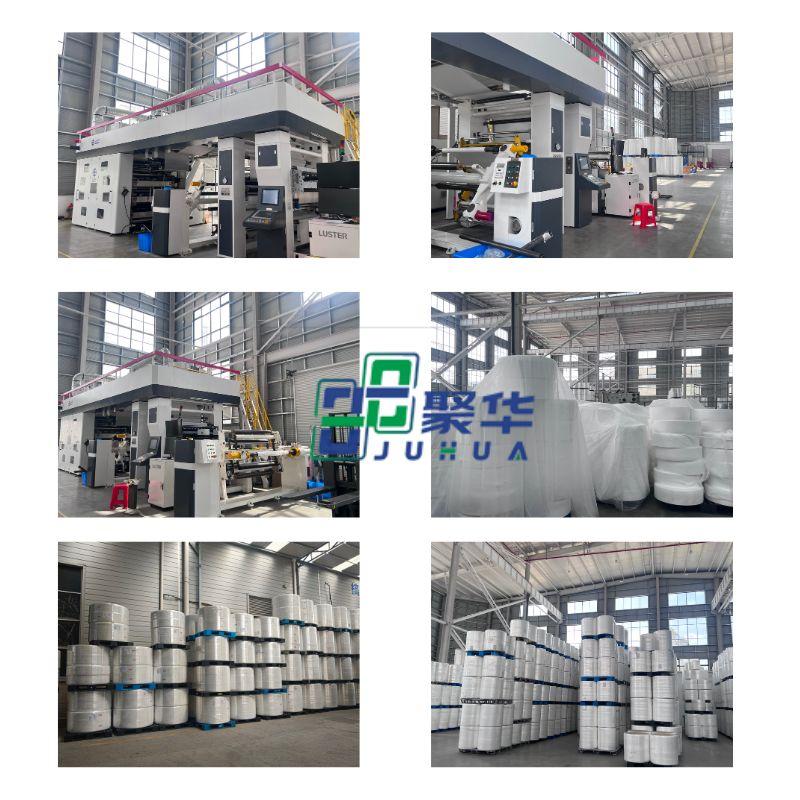

Juhua Factory

Weight: 18 – 50gsm Width: 65mm-3600mm Inner core diameter: 76mm Outer diameter:580-780mm Loading quantity:9-10tons/40HQ Items Unit Requirement Resul...

Weight: 18 – 50gsm Width: 65mm-3600mm Inner core diameter: 76mm Outer diameter:580-780mm Loading quantity:9-10tons/40HQ Items Unit Requirement Resul...

Hot air non woven fabric is made ofcompound fibers which causes no stimulation or allergy to human body. They haveachieved the national standard of hygiene pads production. They te...

Weight: 18 – 50gsm Width: 65mm-3600mm Inner core diameter: 76mm Outer diameter:580-780mm Loading quantity:9-10tons/40HQ Items Unit Requirement Resul...

CATEGORY Soft hydrophilic non woven fabric APPLICATION Topsheet wrapping non woven fabric for medium grade diapers, pull-ups, sanitary napkin and under pads. WIDTH BASI...

Boosting Brand Traffic Growth for South American Customers - Successful Practice of Foreign Trade Disposable Hygiene Products Factory Customer background Our client is a South American brand specializ...

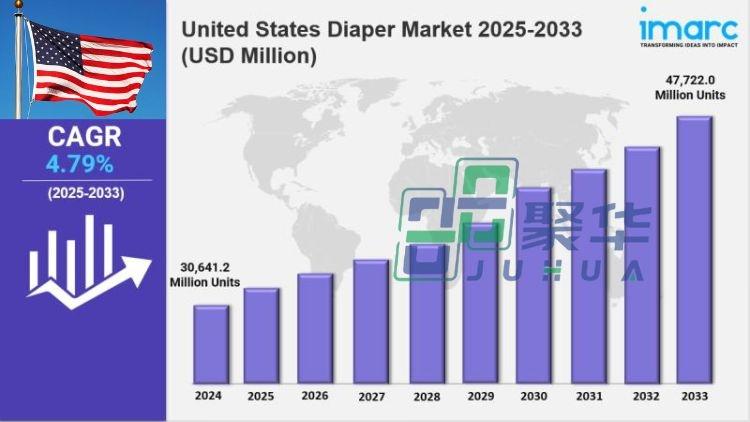

As the global disposable hygiene market continues to expand, the United States remains the world’s largest consumer market for baby diapers. In recent years, demand has been steadily increasing, wit...

Juhua's client is a manufacturer of disposable sanitary products, specializing in the production and research and development of baby diapers, adult incontinence products, and women's sanitary napkins...

Learn more about diaper materials!