Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2025-11-21

In today’s highly competitive hygiene market, the absorption performance of baby diapers has become a key factor that differentiates brands. Absorption speed, retention capacity, rewet control, and long-lasting dryness—all these crucial features are determined by the quality and selection of the diaper’s raw materials. As a professional manufacturer of hygiene raw materials, we understand how each material plays a critical role in the diaper’s absorption system.

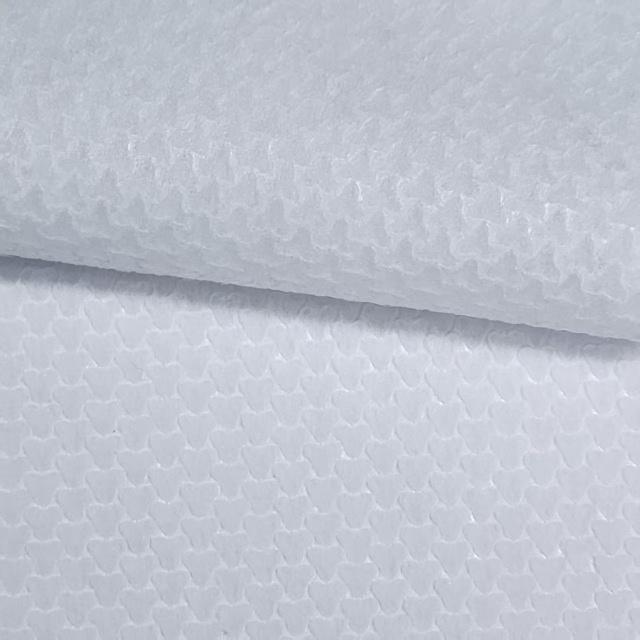

The top sheet is usually made from hot-air nonwoven or spunbond nonwoven fabric, designed to:

Quickly transfer liquid to the core

Keep the surface dry and comfortable

Reduce rewet and skin contact with moisture

Embossed or 3D-perforated designs help speed up liquid penetration.

The ADL, made of colored or spunbond nonwoven, significantly influences:

Liquid distribution speed

How evenly liquid spreads across the diaper

Prevention of localized saturation and leakage

A high-quality ADL ensures the core absorbs efficiently across the entire area.

The core typically consists of SAP (super absorbent polymer) and fluff pulp.

SAP determines total absorption and retention

Fluff pulp provides structure and helps distribute liquid

Higher SAP content increases total absorption but must be balanced to maintain softness and structural stability.

The back sheet, made from PE film or composite nonwoven, affects:

Breathability

Rewet prevention

Strength and comfort

Breathable films help reduce heat buildup and improve overall wearing comfort.

Elastic waistbands, leg cuffs, and leak guards don’t absorb liquid but affect:

Fit and comfort

Side leakage prevention

High-quality spandex and soft nonwoven wrapping ensure a snug fit without irritations.

The absorption performance of a diaper results from the combined engineering of multiple raw materials. Choosing a reliable and experienced raw material supplier is crucial for ensuring product quality and building strong market competitiveness. We provide high-quality nonwoven fabrics, SAP, fluff pulp, breathable films, spandex yarns, and more to support global brands in producing high-performance diapers.